Thermal expansion is usually expressed in one of two ways either volumetric expansion or more commonly linear expansion expressed as a coefficient.

Silicone rubber thermal expansion coefficient.

There have been instances where a seal has ruptured a steel gland due to expansion when heated.

The curing method can be either vulcanized or catalyzed.

The table at.

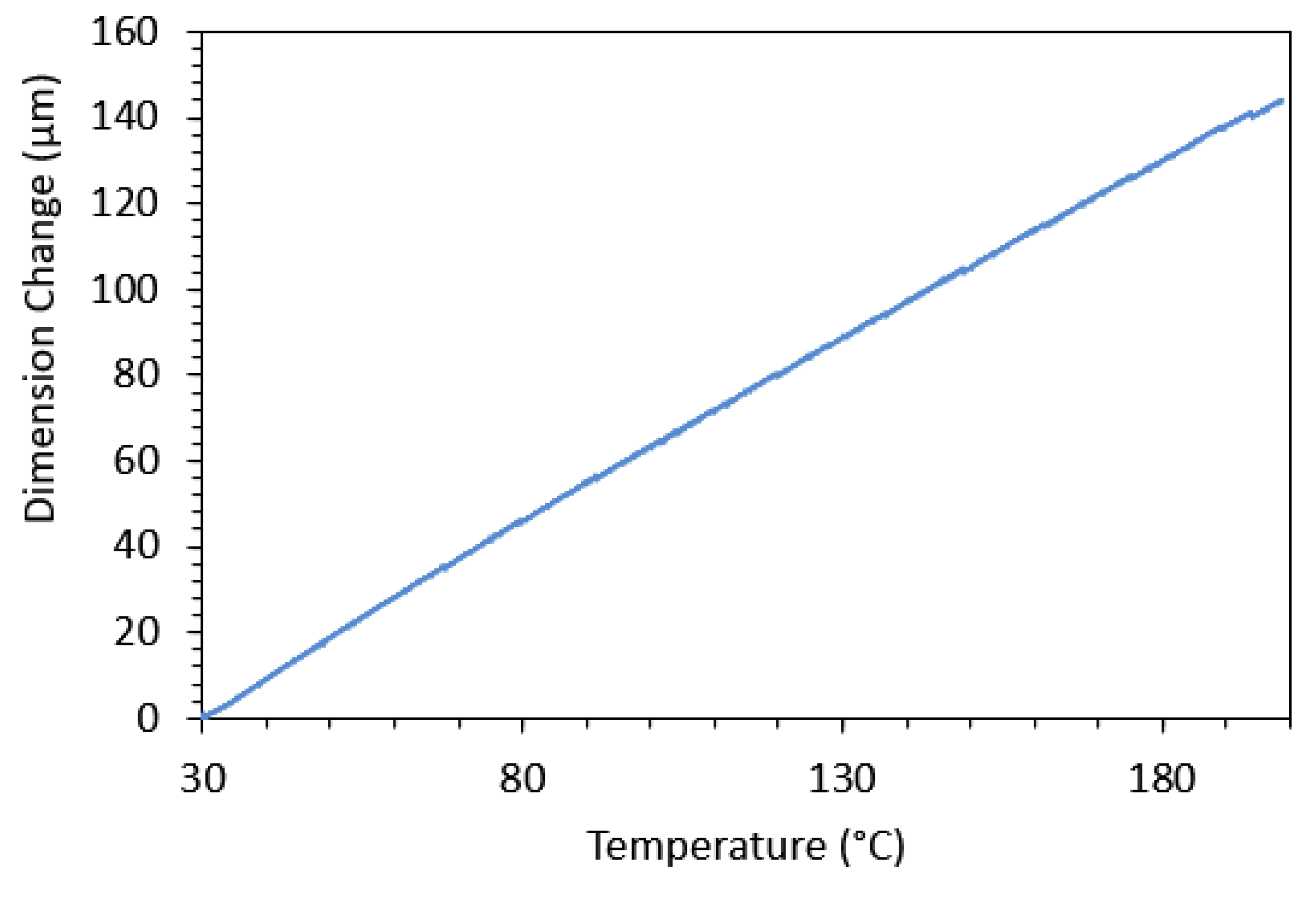

The cte employs reciprocal temperature units k 1 f 1 c 1 etc representing the length change per degree per unit length e g in in f or mm mm c.

Thermodynamics effects of work heat and energy on systems.

Mse supplies stands behind our promise for h igh quality products with competitive pricing and dependable technical support from phd scientists.

Silicones are polymers with a si o si backbone.

These forces are generated by thermal expansion of the rubber and or swelling effect of a fluid.

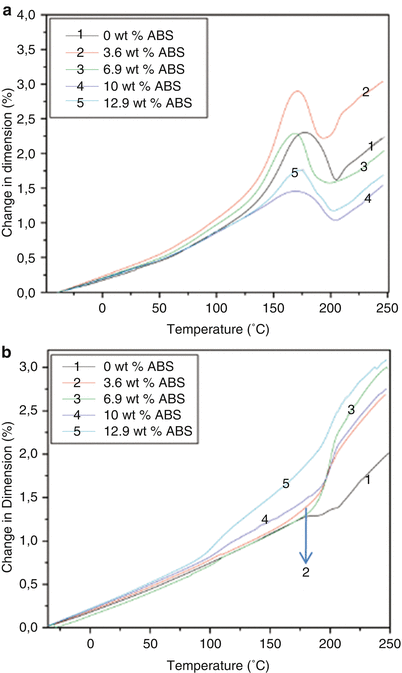

Abs pipes pressure ratings pressure ratings of.

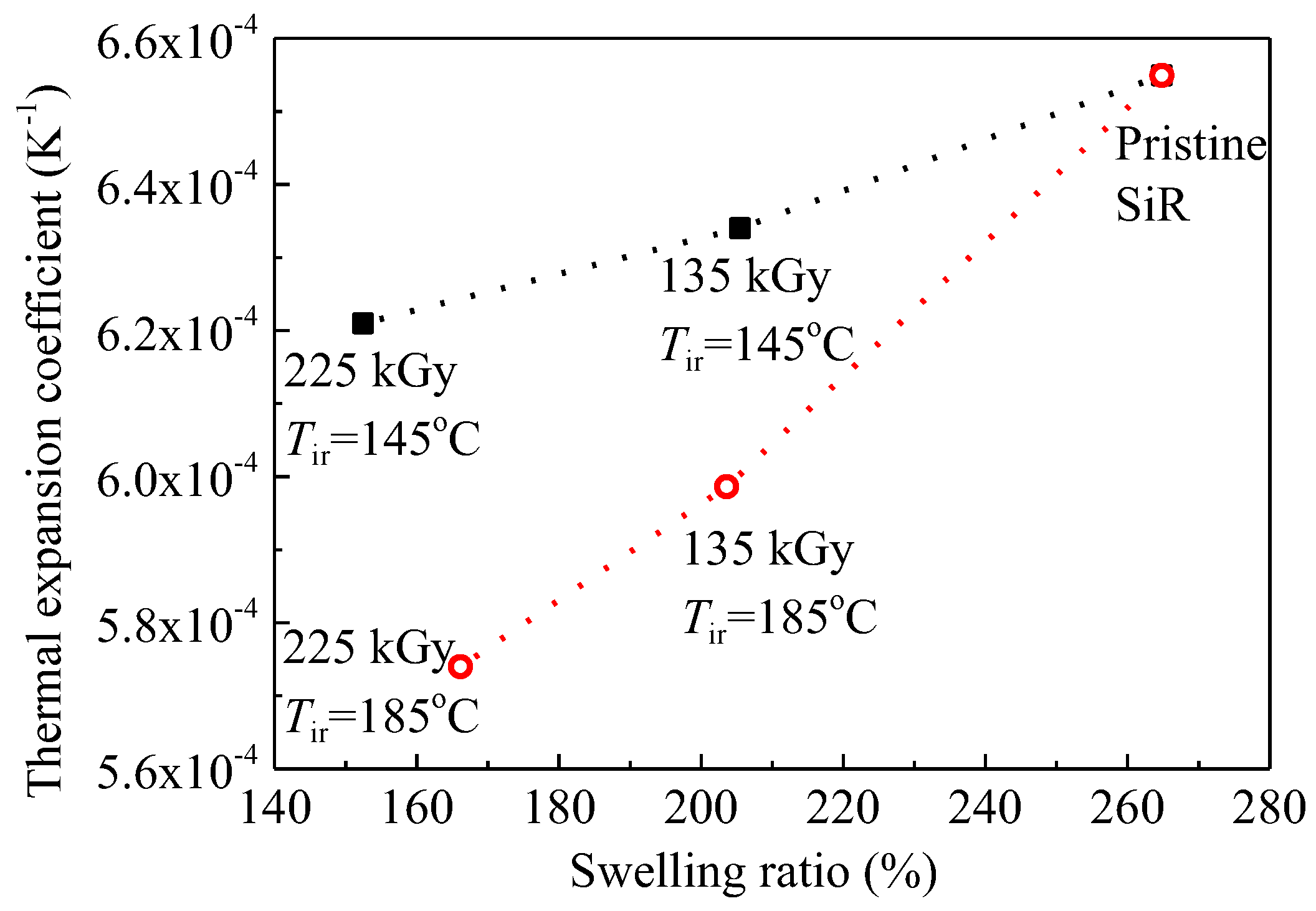

Song in progress in rubber nanocomposites 2017.

Untreated silicone in gel or liquid form will convert to solid after curing.

The overall coefficient is the linear thermal expansion in per degree.

The coefficient of volumetric thermal expansion for all silicone rubber products is in the range of 5 9 to 7 9 x 10 4 4 c.

Key properties include thermal stability chemical stability electrical insulation and low toxicity.

Silicone rubber 190 0 x 10 6 342 0 x 10 6 mech.

For example silicone may expand linearly 5 9e 4 to 7 9e 4 in in c compared to aluminum at 23 0e 6 in in c or steel at 10 8e 6 in in c.

This expansion is an advantage for sealing applications.

Material properties material properties for gases fluids and solids densities specific heats viscosities and more.

Carbons 1 2 to 2 5 x 10 6 2 16 to 4 5 x 10 6.

Temperature expansion thermal expansion of pipes and tubes stainless steel carbon steel copper plastics and more.

Coefficient of thermal expansion silicone has a high thermal expansion coefficient and can be used as a temperature activation method or sensor in the design.

Choose professional dilatometry and thermal expansion coefficient cte testing services from mse analytical services.

Main applications are flexible seals o rings etc.

There are different types depending on functional groups in the structure and curing mechanisms.

2 chart 2 plastics and other non metals.

2 2 4 silicone rubber sir silicone rubber sir is an elastomer composed of silicone containing silicon carbon hydrogen and oxygen in the form of a polymer.

The linear thermal expansion coefficient cte is dependent on the material from which an object is made.

If the seal is completely confined and the gland is 100 filled the dominating force is the force of thermal expansion of the rubber.

Generally linear thermal expansion is most applicable to solids.